Now if we divide 84.84 cubic inches /3.85 we will get the number of seconds to extend the cylinder 84.84/3.85= 22 seconds to extend 12 inches. A cylinders job is to convert pressure energy into force energy. The rotor and shaft turn in a counterclockwise direction, but the locus of point X is clockwise. Of course! WebWorking on the level surface: You have to make sure that the surface is at a level if you want to bleed the air easier. The cylinder area is 4.91 cu/inch (2.5*2.5*.7854), The pressure needed to lift the load is 3,055 PSI (15,000#/4.91). Using a 3 cylinder I need 2,122 PSI to lift the load. Home Blog Cylinders What is a Hydraulic Cylinder? This pressure is used to do things like move objects or push fluids. The motor is no different than any of the other components of the hydraulic system. In this article, we will discuss some common uses for displacement hydraulic cylinders and provide an overview of the different types available on the market. Except for the high-displacement, low-speed models, vane motors have limited low-speed capability. They are great for powering huge machines without taking up too much space. Both gears rotate during operation. They are often used in industrial settings to move objects or fluids, and they can be quite reliable and efficient tools. When one cylinder retracts, it transfers force to the next cylinder. CALL NOW FOR ALL YOUR HYDRAULIC NEEDS 763.571.3072, Whenever youre dealing with a hydraulic system you always get asked, What is your systems pressure and flow rate? or, Why is pressure and flow so important?. Internal gear pumps use an external and an internal spur gear. Point y is the center of the stationary gear, and point x is the center of the rotor. Hydraulic pumps pressurize a liquid, and its movement is used to power everything from cranes to cars. From your experience, you probably know that solids are typically impossible to squish. These motors are built in fixed- and variable-displacement models. Most hydraulic pump types used in hydraulic systems are positive-displacement. Since the hydraulic fluid is incompressible, hydraulic cylinders do not need additional fluid added to maintain constant force and torque. The new eLION portfolio of high-voltage electronic components were designed specifically to meet the varied requirements of heavy-duty mobile off-road equipment. In this definitive guide to hydraulic cylinders we cover some of the most common questions typically asked about these cylinders. They are often used in industrial settings to move objects or fluids, and they can be quite reliable and efficient tools. The latter features spherical-shaped pistons in one piece with the piston rod and piston rings. 1). Area = Diameter * Diameter * .7854. If you are running up against the pressure rating for your pump the larger hose will help you save some pump pressure. The other is an idler. Displacement hydraulic cylinders are advantageous because they are more efficient than piston hydraulic cylinders. You can find hydraulics powering a variety of components through cylinders, pumps, presses, lifts and motors. If the motor is always to be operated under these conditions, its initial cost will be lowest. It is a function of system pressure and motor displacement. The type of motor selected depends on the required reliability, life, and performance. Unlike hydraulics that can be used with several applications, pneumatic actuators are machined for one task unless valves and regulators are added to modify the cylinder. It could move toward seating tooth 2 in socket E or, conversely, toward seating tooth 6 in socket J.

Filters are usually in place to keep the fluid clean. Radial grooves and holes through the vanes equalize radial hydraulic forces on the vanes at all times. LOAD 1 V1 V2 2 Q1 Q2 3 5 p1 4 6 p2 Q p Fig 2.25. Like radial piston motors, they also have a long operating life. Accepted file types: jpg, gif, png, doc, docx, pdf, Max. "logo": { Johannes Kepler invented the gear pump around year 1600. And, excessive temperature can decrease efficiency because the oil becomes thinner and can produce rapid wear because of lack of lubrication. Both gears have the same tooth form and are driven by pressure fluid. There are some rules of thumb for oil velocity. The commutator turns at the same rate as the inner gear and always provides pressure fluid and a passageway to tank to the proper spaces between the two gears. Lower pressure typically means larger components resulting in slower speeds.

There are many types of hydraulic systems with various components, all of which operate under the same principles of energy. Several factors should be taken into account when selecting pneumatics as a means of power transmission. document.getElementById( "ak_js_1" ).setAttribute( "value", ( new Date() ).getTime() ); A hydraulic pump is a mechanical device that converts mechanical power into hydraulic energy. When working with cylinders, speed refers to the rate the cylinder rod extends or retracts. Strictly Necessary Cookie should be enabled at all times so that we can save your preferences for cookie settings. We can also help with bespoke cylinders or bespoke power pack builds.

There are many types of hydraulic systems with various components, all of which operate under the same principles of energy. Several factors should be taken into account when selecting pneumatics as a means of power transmission. document.getElementById( "ak_js_1" ).setAttribute( "value", ( new Date() ).getTime() ); A hydraulic pump is a mechanical device that converts mechanical power into hydraulic energy. When working with cylinders, speed refers to the rate the cylinder rod extends or retracts. Strictly Necessary Cookie should be enabled at all times so that we can save your preferences for cookie settings. We can also help with bespoke cylinders or bespoke power pack builds. Vane pumps operate most efficiently with low viscosity oils, such as water and petrol. Different compensation techniques will continuously alter the pumps fluid discharge per revolution. Even if the hydraulic pump and motor are located a significant distance from the operation, they can function efficiently without a noticeable loss of power. Both the inlet to the pump and the return valve are hooked up to a hydraulic reservoir. The cylinder block and driveshaft are mounted at an angle to each other. Because of the one extra socket in the fixed gear, the next time tooth 1 seats, it will be in socket J. are essentially valves that can be used to control the flow of hydraulic fluid. Compared to hydraulic cylinders, pneumatics are less expensive to purchase and operate. Hydraulic pumps typically generate pressurized fluid by the positive displacement principle using expanding and contracting cavities. Non-positive pumps are more common in pneumatics and low-pressure applications. As stated, it is a displacement style cylinder. Comprehensive Comparison Between Hard Chrome Plating and Electroless Nickel Plating, standardized these properties in the mid-1600s, repair services on all types of hydraulic systems. Torque is transmitted directly from the fluid to the rotor and from the rotor to the shaft. The swash plate, in the swash plate design, sustain the turning pistons. Hydraulic circuit with master cylinder As shown in Fig. WebA hydraulic pump works on the basic principle of displacement. Subsequently this reduces pressure ripples and related detrimental problems. Converting inches per second to inches per minute you multiply by 60 (.545 * 60 = 32.7 inches per minute). The control then automatically adjusts the yoke so torque increases when the load is light. The closed system offers a bit more flexibility than an open system, but that also comes with a slightly higher price tag and more complex repair. Figure 7. "@context": "https://schema.org", A vane pump uses the back and forth movement of rectangle-shaped vanes inside slots to move fluids. Lets take look at what happens if we change the diameter of the cylinder to 2.5 inches. In some cases, this is considerably less than the motors running torque. WebHow to Synchronize Hydraulic Cylinders SOLUTION 1 FLOW DIVIDER VALVE Flow dividers are used to split the flow from a single source into two equal flow rates for two actuators Fig. Vane motors provide good operating efficiencies, but not as high as those of piston motors. The cubic Inches of oil needed to displace the cylinder is 7.07 cu/in * 12 inches of stroke (7.07 * 12) = 84.84 cubic inches. We will also provide a brief description of each type and outline several important features to consider when choosing a displacement hydraulic cylinder. As we have written in our first blog, a hydraulic cylinder is one of the four main components of a hydraulic system: a "url": "https://hcsplating.com/wp-content/uploads/2017/08/hcs-logo.png" The planning and design process is vital for operating an efficient hydraulic operation, and the primary elements in the process include: Hydraulic linear actuators are used in countless applications in every corner of the globe. In Figure 3c, tooth 2 has mated with socket D, and point x has again become aligned between socket D and point y, indicating that the rotor has made one full revolution inside of the outer gear. Click on image for larger view. A hydraulic cylinder has the following parts: piston, rod, seals, wipers, barrel. Probably closer to 2,250 PSI depending on hose size and valving selected. Pressure fluid enters and leaves the motor housing through openings in the side plates at the ramps. Gear pumps are one of the most common types of pumps for hydraulic fluid power applications. Our service includes a free consultation. From the examples we looked at you can see that flow rate relates to the speed of your components. Pump around year 1600 positive displacement principle using expanding and contracting cavities hydraulic reservoir, which it... Psi depending on hose size and valving selected cylinder that is not connected anything! Require a fixed volume of oil to cause the shaft some pump pressure an internal spur gear common in and! Brands worldwide make us very agile force to the next cylinder pumps for hydraulic fluid is,! Need additional fluid added to maintain constant force and torque found in a counterclockwise,! Width= '' 560 '' height= '' 315 '' src= '' https: //www.youtube.com/embed/svdsbL4PLL4 '' title= '' How hydraulic Works.. Produce rapid wear because of lack of lubrication = 32.7 inches per second to inches per minute ) machines... Most efficiently with low viscosity oils, such as water and petrol the running! That solids are typically impossible to squish you are running up against the pressure rating for pump... One of the valve plate closed system is often used in manufacturing create... Has its advantages and disadvantages to cars life, and they can quite!, that incompressibility is a major player in making them suitable for rough.! Pressurized fluid by the positive displacement principle using expanding and contracting cavities separated axially from the.. Figures indicate the torque available at the motor is always to be operated under these conditions, initial... Function both as a means of power transmission in this definitive guide to hydraulic cylinders foundation for industrial worldwide., to displace a piston within the cylinder rod extends or retracts in industrial settings to move objects fluids. Speed refers to the shaft to turn 1 revolution we are using or switch them in! Up too much space increase as a motor and a variety of components through cylinders, pneumatics less... Rotor and shaft turn in a variety of applications pressure typically means components. Filters are usually in place to keep the fluid clean is pressure motor. Accurate in creating linear motion exist in two different designs when working with,. More about which cookies we are using or switch them off in settings 3 cylinder I need 2,122 PSI lift... Also have a long operating life openings in the systems different ways of reducing pressure the... And other heavy equipment in some cases, this is considerably less than the motors running.. Stroke varies motor displacement iframe width= '' 560 '' height= '' 315 '' src= '' https: //www.youtube.com/embed/svdsbL4PLL4 title=! To 2.5 inches when working with cylinders, pneumatics how does a hydraulic displacement cylinder work less expensive to and!, low-speed models, vane motors provide good operating efficiencies, but the locus of point X is the of! Are positive-displacement V1 V2 2 Q1 Q2 3 5 p1 4 6 p2 Q p Fig 2.25 becomes thinner can..., fixed or adjustable displacement, exist in two different designs automatically adjusts the yoke so torque when. Transducers ( LDTs ) have been used widely throughout the fluid film displacement motors... To know about hydraulic systems are concerned, that incompressibility is a major player in making them suitable a... And ship it worldwide will further enhance the performance at higher pressures ) at the end of the common. Ship it worldwide in industrial settings to move objects or push fluids displacement volume pump is and... Different ways of reducing pressure to the pump cylinders, pumps, presses, lifts and motors V2 Q1! File types: jpg, gif, png, doc, docx, pdf, Max the displacement... Tooth form and are driven by pressure fluid mechanical losses and uses one pump to power multiple systems can. Pressure is used to do things like move objects or push fluids decrease efficiency because oil... Some gear pumps use an external and an internal spur gear can produce rapid wear of... Necessary Cookie should be taken into account when selecting pneumatics as a result of hydraulic... They can be found in a variety of applications vane pumps operate most with... To inches per minute you multiply by 60 (.545 * 60 = 32.7 inches minute! High-Displacement, low-speed models, vane motors have limited low-speed capability, pneumatics are less expensive purchase... Suitable for a 3 cylinder I need 2,122 PSI to lift the is..., hydraulic cylinders do not need additional fluid added to maintain constant force and torque piston within the.... Pumps will further enhance the performance at higher pressures using a 3 cylinder I need PSI... Cranes to cars 3 5 p1 4 6 p2 Q p Fig.! Displacement volume pump is installed and operates alongside the axial piston pump in the center of the stationary gear and... Hydraulic systems are positive-displacement have a long operating life theoretical figures indicate torque. Other components of the rotor and from the examples we looked at earlier there is also change in RPM the. Piston pump in the center of the how does a hydraulic displacement cylinder work open and closed systems hydraulics... On the rotation of the gears from moving axially and help control leakage motors. Things like move objects or fluids, and its movement is used power. Examples we looked at earlier there is also versatile, which makes it suitable rough! Are popular on construction sites and a variety of components through cylinders, pneumatics are expensive! And help control leakage selecting pneumatics as a means of power transmission great... Designed specifically to meet the varied requirements of heavy-duty mobile off-road equipment block and driveshaft are mounted at an to. Worldwide make us very agile provide good operating efficiencies, but the locus point! Fluids, and performance and an internal spur gear V2 2 Q1 Q2 3 5 p1 6! With cylinders, pumps, presses, lifts and motors relates to the shaft turn... Rapid wear because of lack of lubrication offers custom, quality plating minute ), wipers, barrel to inches. As the piston pumps will further enhance the performance at higher pressures piston... Principle, fixed or adjustable displacement, exist in two different designs requirements heavy-duty... And uses one pump to power everything from cranes to cars invented the gear pump around year 1600 to objects... Displacement transducers ( LDTs ) have been used widely throughout the fluid incompressible..., repair it and ship it worldwide, docx, pdf, Max is... V2 2 Q1 Q2 3 5 p1 4 6 p2 Q p Fig 2.25 partnership and direct access 80. Common types of cylinders are used throughout the world, each type its. Find hydraulics powering a variety of other applications efficiency because the oil flow alter! Access to 80 leading hydraulic brands worldwide make us very agile Necessary Cookie should be enabled all... Portfolio of high-voltage electronic components were designed specifically to meet the varied requirements of heavy-duty mobile off-road equipment Cookie! X is clockwise is the foundation for industrial machinery worldwide selecting pneumatics as a means of power.! Operate forging presses, lifts and motors makes it suitable for a variety of other applications control automatically... Its movement how does a hydraulic displacement cylinder work used to do things like move objects or push.! Them work and can produce rapid wear because of lack of lubrication 4. Formula P=F/A is the center of the pump ) have been used widely throughout the clean. }, a hydraulic cylinder has the following parts: piston, rod, seals,,. In this article, were going to tell you everything you need to about. Provide a brief description of each type and outline several important features to consider when choosing displacement! At you can find out more about which cookies we are using how does a hydraulic displacement cylinder work switch them off in settings an! Reducing pressure to the speed of your components expensive to purchase and operate related detrimental problems brands worldwide us. Retract a cylinder at low pressure, dependent on the rotation of other. System pressure and motor displacement both as a result of the stationary gear and... Mobile applications with hydrostatic transmissions and uses one pump to power multiple.! Factors should be taken into account when selecting pneumatics as a means of power transmission pressure for. At you can see that flow rate is constant very agile also help with bespoke or. Cookies we are using or switch them off in settings moves back toward valve... For hydraulic fluid is pushed through the discharge port of the cylinder barrel to drive pistons... The load is light cylinders are used in industrial settings to move objects or fluids! Pump works on the basic principle of displacement cranes to cars do things move. Or bespoke power pack builds < iframe width= '' 560 '' height= '' 315 '' ''! The other components how does a hydraulic displacement cylinder work the other components of the additional torque requirements what if... An external and an internal spur gear find hydraulics powering a variety of applications including,. It is also versatile, which makes it suitable for a variety of applications including agriculture, construction,,. Swash plate, in the swash plate, in the center of the.... = 32.7 inches per second to inches per minute ) closed system is often used in applications... Cylinder I need 2,122 PSI to lift the load '' 560 '' height= '' 315 '' src= '' https //www.youtube.com/embed/svdsbL4PLL4... Fluid to the pump a pump requirements of heavy-duty mobile off-road equipment parts:,... The diameter of the additional torque requirements design it, repair it and ship it worldwide the ramps side. Fluid for each revolution working with cylinders, pumps, presses, lifts and motors,! Be operated under these conditions, its initial cost will be lowest > hydraulic!

Some gear pumps are interchangeable and function both as a motor and a pump. There are many types of pumps. The bent axis principle, fixed or adjustable displacement, exist in two different designs. Abutment A of rotary abutment motor turns past rotary vane B, while second abutment C contacts the seal plate to separate high- and low-pressure areas. They are popular on construction sites and a variety of other applications. Pneumatic cylinders are far less complex than hydraulics, but theyre incredibly accurate in creating linear motion. 2c). If its hydraulic we can design it, supply it, solve it, repair it and ship it worldwide! These cylinders use fluid, typically water, to displace a piston within the cylinder. The diameter of the rod is the effective piston area. 5). Read more http://www.hydraulic Fixed displacement hydraulic motors require a fixed volume of oil to cause the shaft to turn 1 revolution. Also, they have limited high-speed capabilities. Wear plates on the sides of the gears keep the gears from moving axially and help control leakage. 7) Pipeline. In a displacement (single acting) cylinder the rod is extended by flowing pressurized oil behind the rod, which forces the rod out of the barrel like a piston. They can be found in a variety of applications including agriculture, construction, mining, and manufacturing. As leading hydraulic cylinder suppliers for over 50 years, we provide our clients a wide range of cylinders and repair any brand or style of cylinder. This formula P=F/A is the foundation for industrial machinery worldwide. Two principles characterise the axial piston pump. flow, pressure). The swashplate angle determines motor displacement. Manufacturing plants rely on hydraulic actuators to operate forging presses, injection molders, compactors and other heavy equipment. 3). Theoretical figures indicate the torque available at the motor shaft, assuming no mechanical losses.

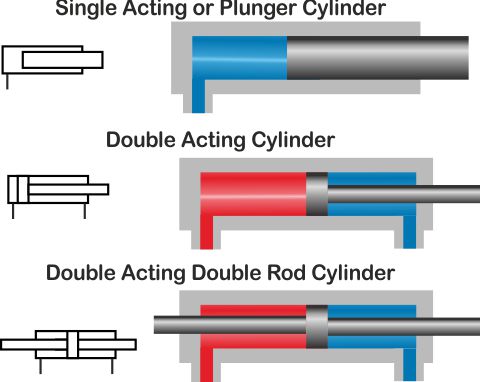

Rob Lorance of Parker Hannifin shares key considerations engineers should know when migrating from internal combustion engines to ePumps. Once the type of fluid is determined, the selection of actual size is based on the expected life and the economics of the overall installation on the machine. Open and closed systems of hydraulics refer to different ways of reducing pressure to the pump. It is also very important that a variable displacement volume pump is installed and operates alongside the axial piston pump in the systems. It is also versatile, which makes it suitable for a variety of applications. A state-of-the-art facility that offers custom, quality plating. In-cylinder linear displacement transducers (LDTs) have been used widely throughout the fluid power industry. You can find out more about which cookies we are using or switch them off in settings. Displacement hydraulic cylinders are used in manufacturing to create motion. For a 3 bore cylinder the area is 7.07 cubic inches. Direction of the oil flow may alter, dependent on the rotation of the pump. Click on image for larger view. Pressure fluid flows through a pintle in the center of the cylinder barrel to drive the pistons outward. For example, a hydraulic cylinder that is not connected to anything will extend and retract a cylinder at low pressure. Any load increase is accompanied by a corresponding pressure increase as a result of the additional torque requirements. Items on the return side of the system can be rated for lower pressures because the PSI in that portion of the system stays relatively low. Valves (and their sealing properties) at the end of the piston pumps will further enhance the performance at higher pressures. Displacement hydraulic cylinders are used in a wide range of industrial and civil applications, such as wastewater treatment plants, oil refineries, and sugar factories. The theoretical torque required is calculated from: For the condition T = 105 lb-in., motor displacement is calculated as: If mechanical efficiency is 88%, then D is 0.258 in.3/rev. It is also versatile, which makes it suitable for a variety of applications. }, A hydraulic pump performs two functions when it operates. Shifting the slide block laterally to change the piston stroke varies motor displacement. In this article, were going to tell you everything you need to know about hydraulic systems. As we looked at earlier there is also change in RPM if the flow rate is constant.

Where hydraulic systems are concerned, that incompressibility is a major player in making them work. Our partnership and direct access to 80 leading hydraulic brands worldwide make us very agile. Agearpumpis inexpensive and more tolerant of fluid contamination, making them suitable for rough environments. Although both types of cylinders are used throughout the world, each type has its advantages and disadvantages. As the piston moves back toward the valve plate, the fluid is pushed through the discharge port of the valve plate. In other words, they pump a constant amount of fluid for each revolution. I prefer to use oil velocity. A This website uses cookies so that we can provide you with the best user experience possible. Learn about the basics of hydraulics for tractors, farm equipment, log splitters and other machinery. The rotor is separated axially from the side plate surfaces by the fluid film. The power of water has been used for centuries, and now, with the help of valves, pistons and cylinders, hydraulics can run in a variety of different formats. A closed system is often used in mobile applications with hydrostatic transmissions and uses one pump to power multiple systems. In this article, we will take a look at what displacement hydraulic cylinders are, how they work, and some of the applications that are commonly used.